The demand for natural stone is on the rise among property owners worldwide, and the use of various natural stone products is expanding and evolving through innovation. However, not every natural stone installation achieves perfection. That’s why processing quality can be a determining factor in the competitive market of natural stones.

Suppliers of granite and marble such as SangVarehStone Company must adhere to several factors to ensure that each product aligns with the intended space. This involves accommodating customer preferences, design aesthetics, and application specifications. All of these potential challenges have a single solution: A comprehensive quality inspection and quality assurance process.

Whether it’s granite tiles or marble tiles, each stone extracted from quarries possesses its unique characteristics. The quality of the stone selected for a specific project is pivotal, influencing how it will appear and perform upon completion. It also dictates its appearance and performance over the course of a decade.

Benefits of Natural stone

Natural stone offers a multitude of benefits in designing and building various architectural projects. Here are some of the key advantages:

Timeless Aesthetics: Natural stone exudes timeless beauty and elegance. It adds a sense of luxury and sophistication to any space, making it a preferred choice for both classic and contemporary designs.

Durability and Longevity: Stone is incredibly durable and can withstand the test of time. It is resistant to wear, weathering, and fading, ensuring that structures maintain their beauty and integrity for generations.

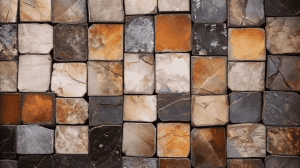

Variety of Options: Natural stone comes in a wide range of colors, patterns, and textures, allowing for endless design possibilities. Whether it’s granite, marble, limestone, travertine, or slate, there’s a stone to match every aesthetic preference.

Low Maintenance: Stone is relatively low maintenance. It is easy to clean and does not require regular refinishing or repainting, saving both time and money over the long term.

Environment-Friendly: Natural stone is a sustainable choice as it is quarried from the earth, and its production has a relatively low environmental impact compared to other building materials. Additionally, stone can be recycled and reused.

Versatility: It can be used in various applications, including flooring, countertops, wall cladding, facades, landscaping, and more. Its versatility makes it suitable for both interior and exterior use.

Increased Property Value: The use of natural stone often enhances the value of a property. Its durability and aesthetic appeal can make a space more desirable to potential buyers or tenants.

Energy Efficiency: Stone has excellent thermal properties, helping to regulate indoor temperatures. This can contribute to energy efficiency in buildings by reducing heating and cooling costs.

Health Benefits: Natural stone is hypoallergenic and does not emit volatile organic compounds (VOCs) like some synthetic materials. It contributes to better indoor air quality and is safe for those with allergies or sensitivities.

Customization: Stone can be cut and shaped to precise specifications, allowing for custom designs and intricate detailing.

Processing Quality Introduction

In the realm of natural stone, the concept of “Processing Quality” stands as a cornerstone for SangVarehStone Company, reflecting our unwavering commitment to excellence. As a natural stone supplier, we understand that the journey from raw quarry blocks to exquisite finished products is one laden with both artistry and precision. In this introduction, we embark on an exploration of what processing quality truly signifies in the world of natural stone. It’s a journey that delves into the meticulous craftsmanship, innovation, and unyielding dedication that define our approach to transforming nature’s bounty into architectural masterpieces. Join us as we unravel the intricacies of processing quality, a realm where each cut, each finish, and each detail breathe life into stone, creating timeless beauty and a lasting legacy.

What exactly is Processing quality?

The term “processing quality” in natural stone refers to the degree of precision, craftsmanship, and attention to detail applied during the various stages of cutting, shaping, and finishing natural stone materials.

It encompasses several factors that determine the final appearance and performance of the stone product. Some aspects of processing quality in natural stone include:

Precision Cutting: The accuracy of cutting stone blocks into slabs, tiles, or other desired shapes is crucial. High-quality processing ensures that the dimensions are consistent, and the edges are straight and clean.

Surface Finish: The quality of the stone’s surface finish, whether it’s polished, honed, brushed, or textured, plays a significant role in its appearance. A well-processed stone will have a smooth and uniform surface without blemishes or irregularities.

Edge Detail: The edges of natural stone pieces can be processed in various ways, such as eased, beveled, or bullnosed. The quality of edge detailing should be consistent and free from chipping or roughness.

Seam Quality: In applications where multiple stone pieces are joined together, like countertops or flooring, the quality of seams is critical. Properly processed seams should be virtually invisible, creating a seamless and cohesive appearance.

Consistency in Color and Veining: Natural stone often exhibits variations in color and veining. Processing quality involves selecting and arranging stone pieces to achieve a visually pleasing and harmonious overall appearance.

Quality of Surface Treatment: If the stone requires surface treatments like sealing or waterproofing, the application of these treatments should be done correctly to enhance the stone’s durability and longevity.

Durability and Resistance: The stone should be processed to maintain its inherent durability and resistance to wear, stains, and other environmental factors. This may involve reinforcing weak areas or filling voids and cracks.

Packaging and Handling: Proper packaging and handling during transportation and installation are essential for preserving the quality of the stone and preventing damage.

Overall, processing quality in natural stone is a combination of skilled craftsmanship, attention to detail, and adherence to industry standards. It directly influences the aesthetics, performance, and lifespan of the stone in various architectural and design applications.

Final Words

In conclusion, at SangVarehStone Company, our unwavering commitment to processing quality transcends the ordinary and transforms natural stone into exquisite works of art. With every cut, every finish, and every detail, we breathe life into stone, ensuring that it not only meets but exceeds the highest standards of beauty, durability, and performance.

Our dedication to processing quality is not merely a business practice; it’s a testament to our passion for creating timeless architectural masterpieces. When you choose SangVarehStone, you choose the pinnacle of craftsmanship and innovation, resulting in stone products that stand the test of time and elevate the aesthetics of every space they grace. Experience the essence of processing quality with us, and let your projects be a testament to uncompromising excellence.

FAQ

- How does natural stone go through the processing phase?

During the processing at the facility, stone blocks are sliced into slabs using high-speed gang saws, which incorporate water during cutting to minimize dust emissions. Despite their speed, these gang saws typically take about two days to complete the cutting of a 20-ton stone block.

2. What characteristics are associated with natural stone?

SHADE VARIATION – All natural stones exhibit shade variations. • FISSURES – Many types of stone naturally contain fissures. • CRACKS – Stone can develop cracks due to mechanical stress during handling, such as during transport, fabrication, or installation.

3. How is stone processing carried out?

Stone blocks are transported from the quarry to the processing yard using heavy equipment, where they are then sawed into slabs and tiles. Further refinement involves trimming the slabs into dimensional stonework, and complex work may be performed using polishing machines, manual methods, or profiling saws.

4. What qualities are considered desirable in good stone?

• APPEARANCE. High-quality stone for facades should have consistent and pleasing coloration. • STRENGTH. A suitable building stone should possess sufficient crushing strength to bear the load of the superstructure. • HARDNESS, TOUGHNESS, AND ABRASION RESISTANCE. • DURABILITY. • TEXTURE. • WORKABILITY. • SEASONING. • POROSITY.

5. What defines the characteristic strength of a stone?

The average compressive strength of the stone is 104.9 MPa when the load is applied parallel to the mineral bands and 86.1 MPa when applied perpendicular to the bands. It is evident that granitoid-gneiss exhibits greater strength when loaded parallel to the mineral bands.